PSGAS Process Summary

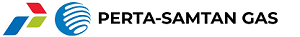

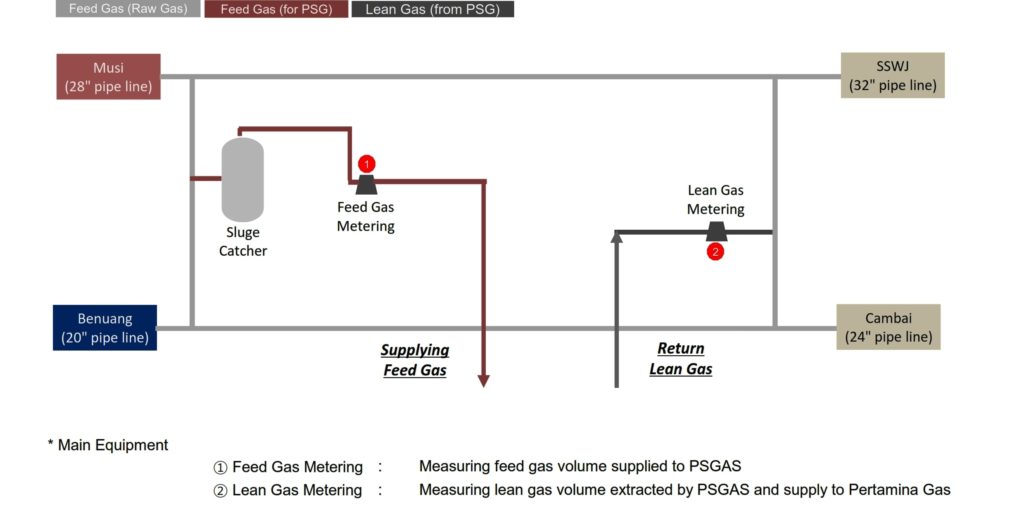

Perta Samtan Gas is designed to extract the optimum amount of natural gas liquids from a combination of gas sources at 250 MMscfd capacity available at the existing SKG-10 Prabumulih Barat gas metering station. An NGL Extraction Plant, which is located adjacent to the SKG-10 metering station, provides the means for extracting the natural gas liquids from the pipeline gases. Following extraction, lean (residue) gas is returned to the metering station and extracted liquids is transferred to a Fractionation plant which is located in the Pertamina Plaju / Sungai Gerong refinery, designation RU III at Palembang. A buried pipeline approximately 89.6kms in length transports the liquids to the refinery. At the refinery the liquid is fractionated and stored with ship loading facilities installed at an existing Jetty and transfer by pipe line to Dom Gas which is located at Plaju.