- LPG / Condensate Delivery

There are 4 (four) storage tanks of LPG and 1 (one) storage tank of Condensate at fractionation plant. The total storage capacity for LPG is 6,000MT which is consisted of 2 x 2,000MT (mixed LPG) and 2 x 1,000MT (propane), and Condensate storage capacity is 25,000bbl.

When we assume the full capacity operation, this storage capacity can cover for 8.5 days production of LPG and 12 days production of Condensate.

(1) Product Delivery Facility

While all of Condensate product is delivered by pipeline, LPG product is delivered by not only pipeline (4.2km) to Pertamina LPG filling station in Pulau Layang but also jetty. In order to use the jetty for product delivery, PT Perta-Samtan Gas has made a jetty lease agreement with Pertamina RUIII to use jetty #1 as a sharing operation condition during 15 (fifteen) years.

The product loading capacity through jetty is LPG 120MT/hr and Condensate 1,500bbl/hr which is considering the pump, metering and loading arm capacity. On the other hand, the LPG loading capacity through pipeline to Pulau Layag is 50MT/hr.

(2) Product Receiving Facility

Produced LPG is delivered to LPG filling station in Pulau Layang by pipeline to meet the LPG demand in South Sumatera region with daily delivery quantity about 300~400MT. Pertamina LPG storage capacity in Pulau Layang is about 1,255MT, and Pertamina distributes LPG to South Sumatera via tank truck (15 tons) and LPG cylinder (3~50kg).

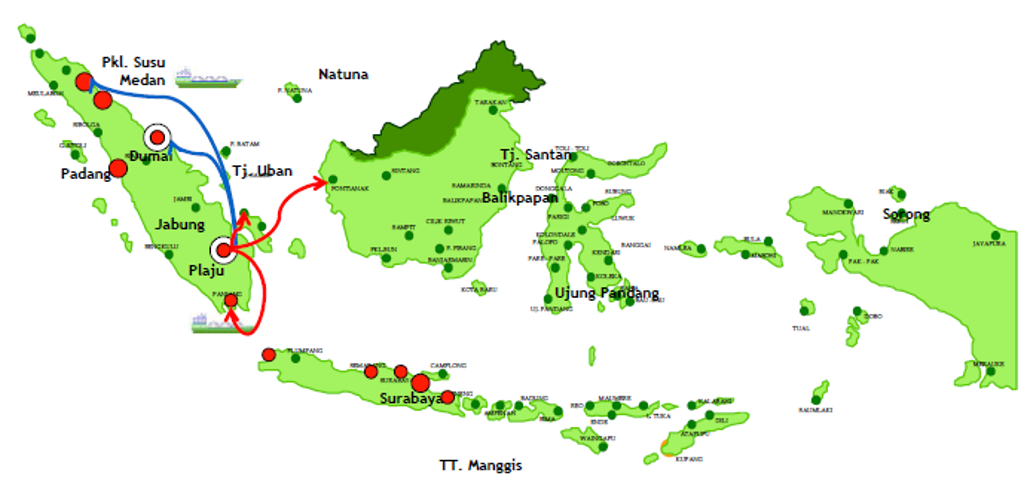

Remaining LPG product is delivered to Dumai, Pangkalan Susu, Pontianak and Panjang by vessel (arranged by ISC, capacity 1,000~1,500MT per each vessel).

LPG distribution scheme by vessel is as follows, and 1 round trip is required for 7~10 days.

Meanwhile, Condensate is belongs to Pertamina EP, and whole product is delivered to Pertamina Refinery Unit III by pipeline (owned by Pertamina EP).

- PT Perta-Samtan Gas’s Delivery System

Whole product delivery flow can be divided into 3 (three) steps ;

(a) Planning Schedule (b) Monitoring Schedule (c) Implementing Delivery.

And there are several management factors in each steps as follows:

| Step | Management Factors | Remarks |

| Planning Schedule | Feed gas supply rate (monthly) | Confirm with Pertamina EP |

| LPG/Condensate production | Forecast based on the feed gas rate/recovery rate/production day etc. | |

| LPG vessel/pipeline delivery ratio (monthly) | Confirm with Pertamina ISC | |

| Monthly vessel lifting frequency | ||

| Monitoring Schedule | Daily LPG/Condensate production and inventory | Based on tank gauging (current condition) |

| LPG/Condensate stock forecast | Weekly/monthly forecast based on delivery plan | |

| LPG production & delivery tank nomination | Stock simulation for each tank | |

| LPG pre sample test | Conduct 3 days before vessel lifting schedule | |

| Implementing Delivery | Final sample test result | Conduct before start delivery |

| Loading time | Management consumed loading time from all fast upto loading finished | |

| Loss management |

Vessel) comparing number between tank gauging, metering and vessel gauging Pipeline) comparing number between tank gauging and metering |